More Than 120 Years of Roll Forming Services

Since 1904, the Dahlstrom® name has been synonymous with an accepted standard of excellence in custom roll formed products.

When you work with Dahlstrom Roll Form, you get the advantage of a roll forming services provider with more than 120 years of experience to help you maximize the advantages of this technology. Shore up your supply chain with our:

- 99.5% on-time delivery rate (benchmark is 70-80% in metal manufacturing)

- A PPM defect rate of less than 4,000 (on par with the best companies in the world in ANY industry)

- Kanban inventory management and quarterly forecasting (you only pay for what you need)

- Custom packaging division

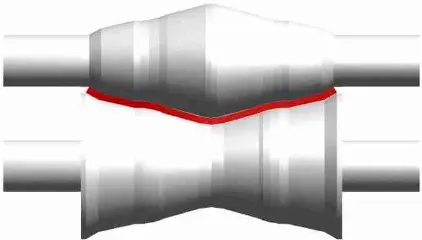

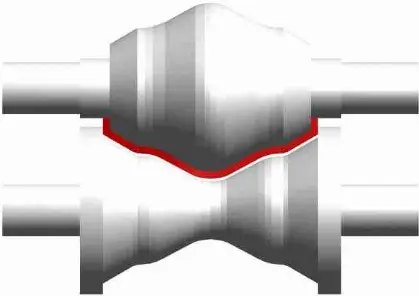

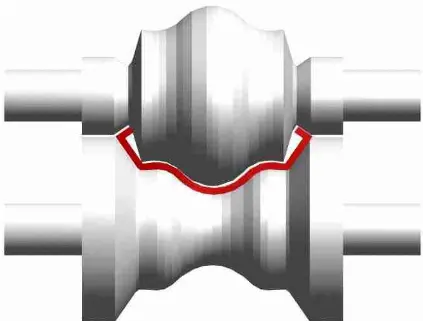

What is Roll Forming?

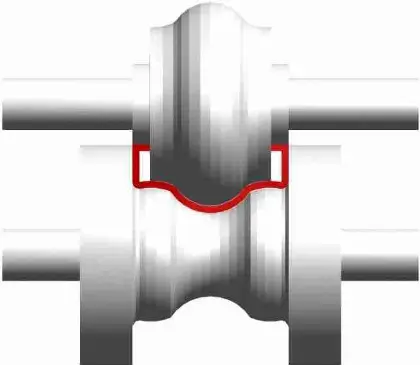

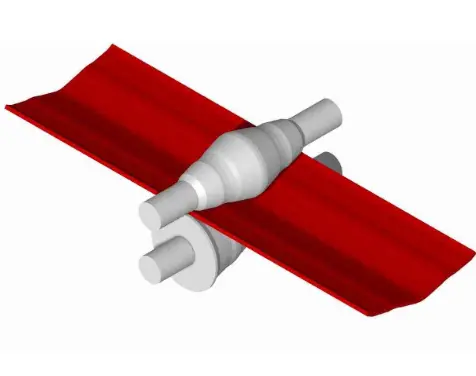

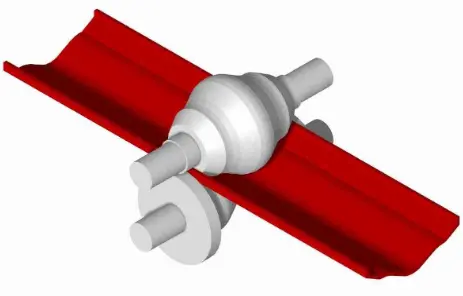

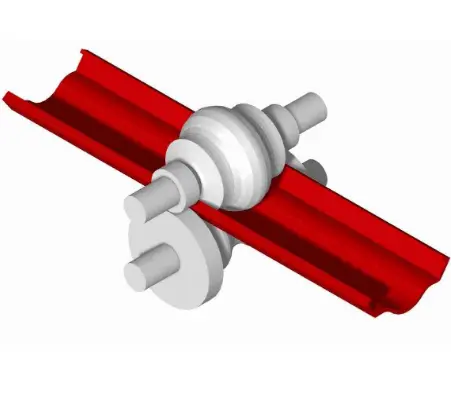

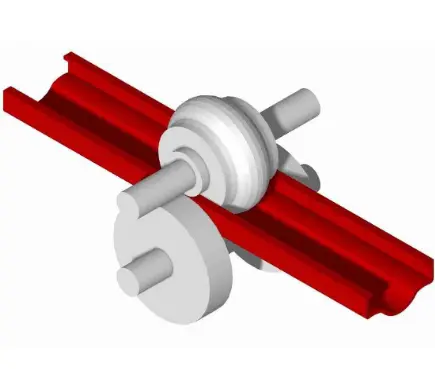

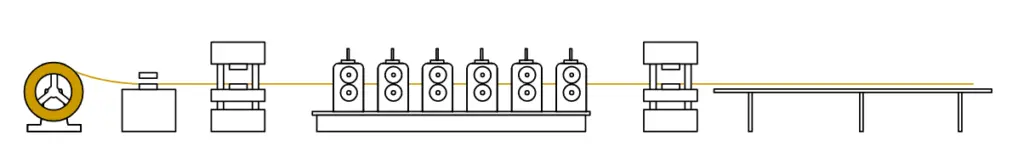

Roll forming is the process of gradually bending flat sheet metal into a longitudinal, uniform profile by passing it through a series of mated tool dies. It’s the most economical manufacturing process for the mass production of:

- Angles

- Channels (C, J, Box, Hat)

- Long components with holes

- Complex shapes with multiple bends

Roll forming also allows for the cheap, simple addition of IN-LINE punching features like:

- Holes

- Notches

- Slots

- Embossing

Designing these elements into custom tools eliminates the need for slow, expensive secondary operations. Consequently, roll forming lowers your

production costs and reduces your lead times.

Available Roll Forming Materials:

Dahlstrom can form a wide variety of metals, including:

- Cold rolled steel

- Hot rolled, pickled and oiled steel

- High-strength, low-alloy steel

- Galvanized / galvannealed steel

- Stainless steel

- Aluminum

- Copper

- Brass

- Bronze

Note: welded shapes, or those with tooling NOT designed to bend high-strength/heavy material, are only available in steel.

Material Thickness & Lengths

Dahlstrom can currently form material thicknesses ranging from .012″ – .200″.

Dahlstrom can cut most shapes to specific lengths ranging from 2’ to 40’.

Tolerances

Many cross-sectional shape dimensions can be held within +/- .030″. Tighter and/or looser tolerances depend on customer requirements, processing capabilities, and tool investment.

Punched or Pierced Features

Depending on the complexity of a component, roll forming shapes like holes, notches, and cut-outs are either pre-punched in line or post-punched as a near-line secondary operation.

Contact Dahlstrom and put a century-plus of custom roll forming services in your corner.