Data Storage

With thousands of servers housed in expansive facilities worldwide, these centers rely on meticulously crafted server racks, made

possible through roll forming.

Roll Forming for Server Racks

Data centers are vital to our everyday life. They house the servers that store data we regularly use: social media, online banking, and streaming services, just to name a few. There are about 8,000 data centers around the world, with 2,600 located in the United States. Data centers average 100,000 square feet, with the largest encompassing 6.3 million square feet.

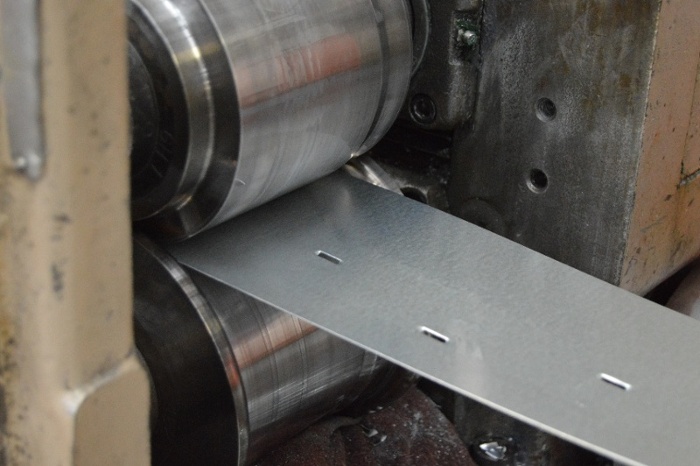

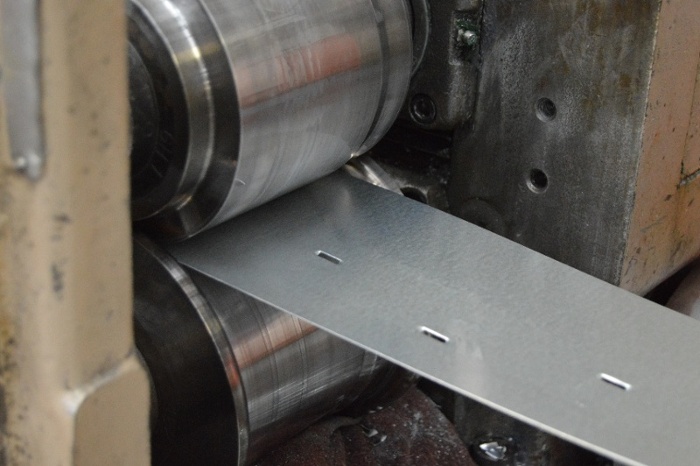

Housed within each center are rows upon rows of server racks housing hundreds, if not thousands, of servers. These storage units are made up of long, slender metal parts, similar to what you see in a warehouse. Server racks need accurate and consistent punching for holes for one part to line up with another.

Roll forming is an efficient and cost-effective method of producing various parts of data storage racks, including:

Structural joists

Main frames

Mounting rails

Side panels

Doors

Cable management bars

Roll Forming Advantages

Server rack systems need a high volume of long, slender parts, which is roll forming’s specialty. Roll forming is a highly repeatable process. Once the tooling is in place, roll forming produces components more consistently than other metal shaping processes, even over long runs.

Why should you consider roll forming for power distribution components? Roll forming can fabricate parts with:

- Huge volumes

- Tolerance control

- Complex profiles

- Inline punching for accepting mating parts

- Tricky hole patterns

Hole punching, bending, and cutting to length can easily fit into one continuous process rather than separate steps. Roll forming is a more cost-effective and productive method in all these cases.

WHY DAHLSTROM?

Dahlstrom Roll Form has created superior custom roll formed products since 1904.

Along with consistently producing the highest-quality components in an ISO 9001:2015 facility, Dahlstrom offers the following services to all of our customers:

- Dedicated account managers

- Personalized quarterly reviews

- 99.5% on-time delivery commitment

- Custom vendor-managed inventory

- Expert tool design & part optimization

- Pass-through raw material pricing

- Tailored packaging & logistics

- Minor assembly & washing

Recent Posts

The OEM Guide to High-Performance Server Rack Manufacturing

Why Roll Forming Is the Best Fit for Warehouse Shelving Components