OEM Roll Forming Manufacturer for Custom Roll Formed Parts

Delivering precision sheet metal roll forming solutions for OEMs since 1904

Your Trusted Custom Roll Forming Manufacturers

Dahlstrom Roll Form partners with OEMs to manufacture high-volume roll formed components engineered for repeatability, efficiency, and long-term production stability.

Since 1904, we have operated as a precision roll forming manufacturer focused on delivering custom roll formed parts with consistent quality and dependable lead times.

Built for OEM Production Requirements

Our systems are designed to support recurring production programs, minimize downtime, and protect your supply chain continuity.

99.5% On-Time Delivery Rate

Custom Packaging Solutions

PPM defect rate below 4,000

Integrated in-line punching and forming

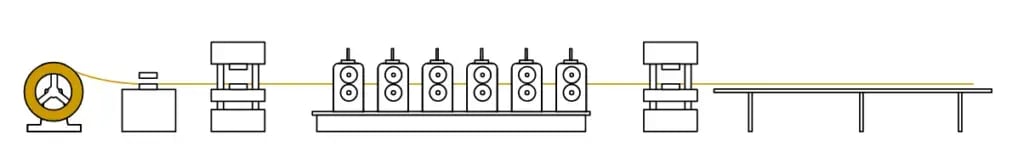

What is Roll Forming?

Roll forming is a continuous metal forming process that gradually bends flat sheet metal into a longitudinal, uniform profile by passing it through a series of precision roll stations.

Because the material remains in motion throughout the process, roll forming is ideal for producing high volumes of consistent, repeatable parts.

Unlike press braking or stamping, roll forming distributes deformation across multiple forming passes.

Each roll station makes a small, controlled adjustment to the profile until the final geometry is achieved.

Roll forming turns a coiled strip of sheet metal into the desired shape by passing that metal through a progressive series of mated dies.

Roll forming is a cost-effective way to achieve the production of long, complex metal shapes with multiple bends and/or punch patterns. It is popular for high-volume projects like:

- Solar panel racking

- Bus bars & wire raceways

- Elevator/escalator components

- Shelving supports

You see roll formed products all the time. For example, guide rails on the highway are usually manufactured using this metal fabrication method.

.png?width=732&height=522&name=DSC_0113-2-768x321-1%201%20(1).png)

Do You Need a Roll Former or a Roll Bender?

While roll bending and roll forming are types of metal forming, they are not the same. Learn when you may need a roll bender and not a roll former.

Common Roll Formed Profiles

Angles & Channels

C, J, Box, Hat

Long Components

in-line features

Complex Shapes & Bends

In-Line Secondary Operations

Roll forming lines can integrate additional processes to reduce downstream handling and secondary labor:

- Hole punching

- Notching

- Slotting

- Embossing

By designing these elements into the tooling and line layout, manufacturers can eliminate slow, expensive secondary operations — reducing total production cost and improving lead time.

Understanding what roll forming is sets the foundation. The next step is seeing how the process unfolds inside a roll forming line — from coil entry through final cutoff and packaging.

How Does Roll Forming Work?

Roll forming converts flat coil into a finished profile through a continuous, progressive shaping sequence. Each station along the line performs a specific forming function, ensuring dimensional accuracy and repeatable quality.

Roll Forming Industries & Applications

Our roll formed components support production across demanding industries, including:

Each application benefits from production consistency, integrated feature punching, and scalable output.

Available Roll Forming Materials

We support carbon steel, stainless, and aluminum roll forming for OEM applications where weight reduction, corrosion resistance, or finish quality matter.

Dahlstrom can form a wide variety of metals, including:

- Cold rolled steel

- Hot rolled, pickled and oiled steel

- High-strength, low-alloy steel

- Galvanized/galvannealed steel

- Aluminum

- Copper

- Brass

- Bronze

- ZAM®

Note: Welded shapes, or those with tooling NOT designed to bend high-strength/heavy material, are only available in steel.

Punched or Pierced Features

Roll forming shapes like holes, notches, and cut-outs are either pre-punched in line or post-punched as a near-line secondary operation.

Tolerances

Many cross-sectional shape dimensions can be held within +/- .030″. Tighter and/or looser tolerances depend on customer requirements, processing capabilities, and tool investment.

Material Thickness & Lengths

Dahlstrom can form material thicknesses ranging from .012″ – .200″. We can cut most shapes to specific lengths ranging from 2’ to 40’.

Request a Custom Quote

Enhance your manufacturing efficiency with custom roll forming solutions. Request your quote today and discover the difference in precision and performance.