Power Distribution

Data centers, hospitals, and retail outlets all rely on a critical backbone: the power distribution system that keeps their essential operations running.

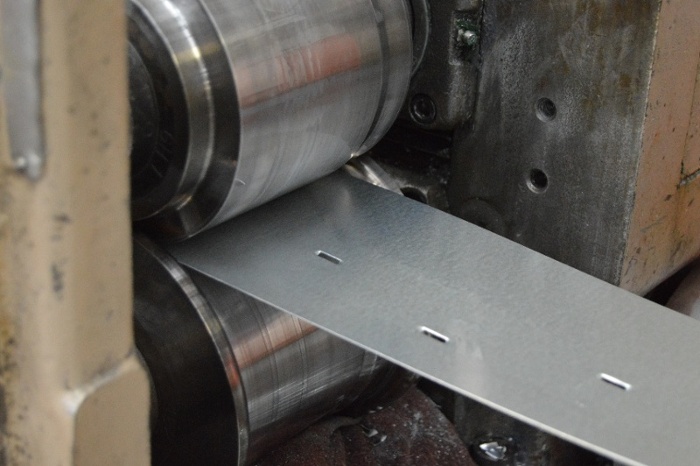

Roll Forming for Power Distribution Systems

Power distribution systems are highly proprietary and require thousands of feet of metal components per project. Consequently, custom roll formed parts are critical in both current-carrying and non-current-carrying equipment. These long and slender metal parts are perfect for roll forming.

Cable trays and wire raceways are often made of galvanized steel. Steel is structurally sound and conductive, enabling the part to be grounded. Roll forming machines can handle bare or prepainted steel. Busbars are made of copper or aluminum.

Dahlstrom Roll Form creates proprietary profiles that carry current and accept mating parts.

Roll Forming Advantages

Power distribution systems need a high volume of long, slender parts, which is roll forming’s specialty. Roll forming is a highly repeatable process. Once the tooling is in place, roll forming produces components more consistently than other metal shaping processes, even over long runs.

Why should you consider roll forming for power distribution components? Roll forming can fabricate parts with:

- Huge volumes

- Tolerance control

- Complex profiles

- Specialized materials like tin-plated copper

- Inline punching for accepting mating parts

- Tricky hole patterns

Hole punching, bending, and cutting to length can easily fit into one continuous process rather than separate steps. Roll forming is a more cost-effective and productive method in all these cases.

WHY DAHLSTROM?

Dahlstrom Roll Form has created superior custom roll formed products since 1904.

Along with consistently producing the highest-quality components in an ISO 9001:2015 facility, Dahlstrom offers the following services to all of our customers:

- Dedicated account managers

- Personalized quarterly reviews

- 99.5% on-time delivery commitment

- Custom vendor-managed inventory

- Expert tool design & part optimization

- Pass-through raw material pricing

- Tailored packaging & logistics

- Minor assembly & washing

Recent Posts

Why Roll Forming Is the Best Fit for Warehouse Shelving Components

9 Design Tips for Ground-Mounted Solar Structures